Four main types of system breakdown

System thinking involves multiple descriptions of the system. But how does it differ from the general philosophical/ontological idea of multiple descriptions of a situation by different agents pursuing different goals? The difference lies in the fact that system thinking today identifies four main types of system breakdown, and these types receive different descriptions/views:

- the familiar description of subsystems as role/functional objects of system operation/exploitation/functioning/operations (description of "how it works," time of use, often called system breakdown, also known as functional breakdown),

- as constructive/physical modules of time of creation (description of "what it is made of," product/module breakdown), and

- as places in space where system parts are located (where in the Universe system parts are located, spatial division).

- As cost components (what money and other resources will be needed, cost breakdown)

These four descriptions of system breakdown have become the main ones in most variations of the system approach over the past thirty years, although not the only ones (and the cost breakdown has only recently become one of the mandatory ones, this understanding has emerged in engineering projects in the last decade).

It is important to note: breakdowns (trees) are not the only system descriptions! System descriptions are only as relevant as they discuss system aspects in their breakdown (what is described by various descriptions is taken from the corresponding breakdowns). For example, one can talk about the functional decomposition of the system, but one can also discuss the functional model as the result of 1D modeling (in one-dimensional models, something "flows," so functional parameters are determined along these hypothetical flow lines - electrical, hydraulic circuits, heat transfer through pipelines, cargo flows in logistic/supply chains, etc.). 1D modelers are often called "physical modelers" as they can calculate currents and voltages in electrical circuits, pressures and flow rates in hydraulic systems. However, they, of course, represent systems more complexly than just "breakdowns."

But for now, let's focus on breakdowns (they are breakdowns themselves in the real world - all their objects are real, but we can also talk about breakdown descriptions. In everyday life, this difference between breakdown as real physical objects and breakdown description as information, method as behavior "in life" and method description as information about behavior (theory/discipline/knowledge), ontology (which objects in life, the objects themselves), and ontological descriptions (how we describe objects in life, information about objects) fades, and descriptions are often discussed using the main term "about reality": breakdown, method, ontology where we should talk about the breakdown description, method description, ontology description. How can you understand what is meant? Only from the context, and when it is completely unclear, it is right to ask for clarification.

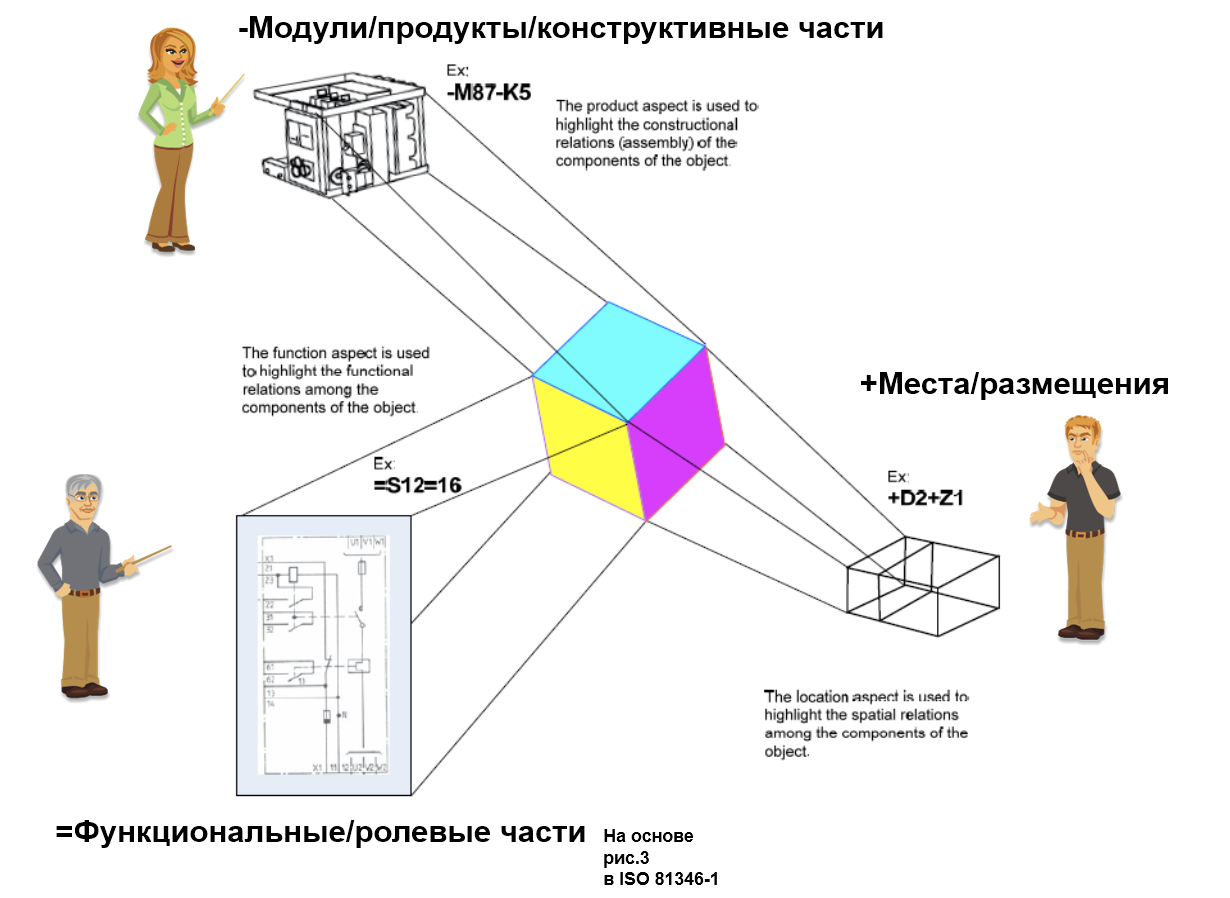

Here is a modification of the diagram from the IEC 81346-1:2022 standard, illustrating (and it does not yet include the cost breakdown, you can imagine it as some financial calculation, for example, "total cost of ownership"[1]):

In the picture, three project roles that are interested in different system descriptions represented by figurines. Remember that roles are just roles: they can be played by one person or whole groups of people with their tools and equipment. In the picture, three different people play three different roles (but the picture depicts only three aspects as an example, even in IEC 81346-1:2022, these aspects are five, including a type as an arbitrary grouping by some property and "other," where everything else is included - logistics, cost division, administrative subordination. Our cost breakdown according to this standard will be in this "other" breakdown, other aspects).

Each project role sees its system divided into certain types of interacting parts, symbolically depicted by colors. At a minimum in the system approach, four main types/types of system parts should be highlighted:

- Functional/role parts (functional elements, but we translate as "parts" because elements do not imply further divisibility, and we always remember it; role elements[2]), the discussion of the interaction of which allows to answer the question of how the system works, how it performs its function/role in its supra system. This will definitely be a discussion of the time of exploitation/work/operations/use/service. The picture shows a schematic electrical diagram that provides a description of the functional/role parts of the system and their connections (connectors). These functional/role parts perform their function in the system through connections with other functional parts, changing their state from this interaction and changing the states of other parts.

- Modules/products/constructives/constructive parts (modules, products, components as ordered units, assembly units, logistic units, constructs) - this type of parts answers the question of what to assemble and how to connect through interfaces (interface) the modules of the system, answers the question "how to build the system," discusses the time of creation. The time of exploitation, "how to operate" according to these diagrams cannot be discussed!

- Places (locations) or allocations that allow to answer the question of where to find parts of the system, how it is composed in space. Usually, these places are given for run-time, and allocations are made for design-time defined modules. The place/allocation is important for the co-location of role and physical objects in run-time: if both are in the same place at the same time, they are the same object. The picture shows compartments where the system is assembled and where it then operates, but it is not clear what the system is made of and how it operates.

- Cost parts (costs) that allow to discuss the expenses/costs of the system, not only for the development period, but for the entire life cycle (for materials, for work on creation, for work and materials during the exploitation, maintenance, upgrade, for work on decommissioning the system taken out of operation.

One of the recent trends is the inclusion of a fifth breakdown - work breakdown structure (WBS) in these system breakdowns, but this has not yet been fully established in engineering culture, it is only a "candidate for mandatory breakdowns." For each system of interest, there is a creator who performs work on it (conceiving, formulating the concept of use, designing with decision-making on system and architectural solutions, manufacturing with consideration of "manufacturing methods"/"production technology," justifying successfulness, and then integrating it into the system - and continues to do all this in the system's development process). All these works need to be somehow taken into account, they also need to be somehow designed, distributed among contractors. This is done in every project. Therefore, the breakdown of work on creation and development of the system is often considered as mandatory system descriptions today, but we have not yet included them (and here it is even irrelevant that the description of work belongs to the description of the creator of the system, the cost description also significantly touches on the cost of creator's services, so this is just a continuation of the trend towards the full implementation of the ideas of second-generation system thinking, where "the system is always thought of as part of a supra system, but also remembered that it has creators").

It is often thought that breaking down work on creating and developing a system can somehow be done up-front, referring to project management and WBS from there, but this is not the case - details are provided in the "System Management" course. In any case, this is already a description not so much of the system of interest itself but of the system of creation (it is the creation system that is operational, and this work is described), although each work has a clear link to the object of that work: some important part of the system of interest. But let's wait until this fifth description becomes fully accepted. And right now it is just a trend.

Even cost parts, which have relatively recently appeared as a full-fledged system description object, are not entirely about the system of interest (as they touch not only the cost of raw materials but also the cost of the creator's work, as well as the expenses on maintaining the operability of the system during exploitation - and it still needs to be settled how to calculate all that).

All these parts highlighted according to different role interests in the same whole system, represented by a cube with colored faces - and each role gets the opportunity to discuss its concern/important characteristic through a description conveniently arranged for this purpose:

- The one interested in "how it works" gets a functional/principal/flow schematic with connections of functional/role parts.

- The one interested in "what products to assemble" gets a description of the structure: products/modules and their interfaces to each other.

- The one interested in "where to find/where to put" gets a description of the locations where the system is located, the composition.

- The one not depicted in the picture interested in "how much it costs" gets a description of how much it costs to create, operate, decommission the system. In recent years, Total Cost of Ownership (TCO) descriptions are considered necessary.

- And there is also the one not depicted on the picture interested in WBS/"what works are carried out with this."

- ... and there are many such parties interested in different aspects/variations of breakdowns, the minimum descriptions were shown here.

System levels are defined according to the main breakdown in system thinking - functional! Therefore, functional breakdown is often called system breakdown/system breakdown structure. And what about the other breakdowns? They are just breakdowns.

In principle, this terminology of "system breakdown" as functional is not always followed. The system itself is most often simultaneously a functional part of the suprasystem, and a constructive part of the same suprasystem, takes a certain composition place in this suprasystem, and requires expenses and the performance of certain works on itself. To some extent, any of the main breakdowns is systemic. But in engineering, usually, when talking about system breakdown and system levels, it is specifically the functional breakdown that is meant, not the constructive, spatial, or cost-related breakdown.

We intentionally mention in the previous paragraph that the system is a part of a suprasystem, not dividing the system into subsystems. The main flow of system thinking is from the system as part to the suprasystem as a whole. But this reasoning can be applied at any system level, including for subsystems, sub-subsystems, suprasystems, and super-suprasystems.

When we talk about system levels, it is worth clarifying: which of the breakdowns are we referring to: which of the main ones (functional, constructive, allocations, cost-related), or some others (works on creation, manufacturing sequence, assembly sequence, environmental impact, etc. - there are many different variations!)

Sometimes the functional part is referred to as a component, and sometimes as a constructive one (for example, a separately purchased product according to IEC 81346-1:2022). Be careful: in different subject areas, this word is used differently. Also, in contemporary Russian, the word component/component is used almost equally in the feminine and masculine genders, there is no norm on this point. ↩︎